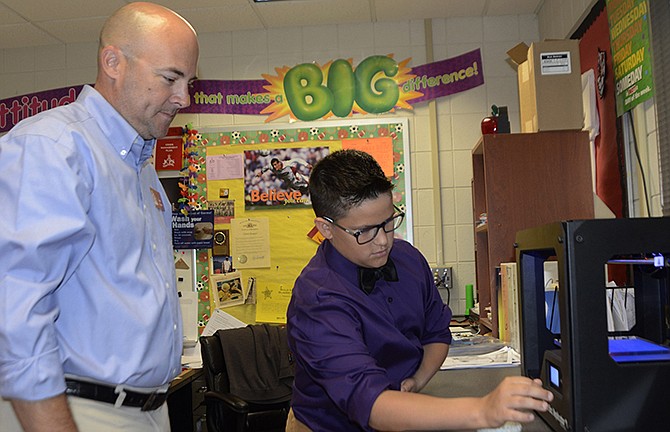

As this school year came to a close, teachers at Lewis and Clark Middle School tinkered with a new instrument - a 3-D printer - they plan to fully integrate into their lessons next fall.

The printer - a MakerBot Replicator 2 - will allow students to design projects on CAD (computer-aided design) software and see their models brought to life in three dimensions. The machine will be used in a Gateway to Technology class focusing on pre-engineering topics.

"I've had it about two weeks and I've experienced a few successes and failures," teacher Garth Haugen said.

Haugen hopes having the 3-D printer will help his student better understand the design process.

Although his students could design new products using Autodesk Inventor software on the computer, they couldn't bring their work in to the real world. To see what they had designed, they had to use hot glue, craft sticks, toothpicks, etc.

With the 3-D printer, they can.

Here's how it works. Behind the machine is a spool of flexible plastic wire, similar to weed-eater string. An element heats the wire, melting it slightly, to become pliable enough to take on a new shape. Skittering into a robotic fashion, a motorized "arm" basically builds the new item from the bottom up.

"It lays it (the softened plastic) down in strings," Haugen explained.

So far students have built some pre-programmed designs - such a screw, a bolt and a bracelet. Before school ended, they also worked on their own project: a toddler's workbench with square and round pegs and a small mallet.

Ben Harrison, an eighth-grader in Haugen's class, said he could see the applications for the machine.

"If a company wanted to design something new, they would have an idea of what their product looked like," he said.

Eighth-grader Kord Pearson said when the students first were asked to design something for the 3-D printer, the task seemed difficult.

"At first we had to call the teacher over," he said. "But now Ben and I help the other students."

Haugen wasn't certain what the district paid for the machine, but they retail online for about $2,000.

He first heard about the machine after talking with a colleague from the St. Louis region. He added it's taken him a few tries to work out the MakerBot's kinks.

"There's a learning curve for the teacher, too," he said wryly.